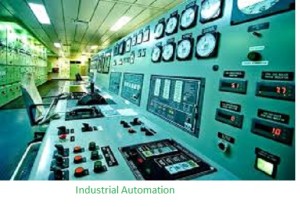

Industrial Automation

A glimpse of Industrial Automation

With the reference of the word Automation, we can understand that Automation is the wonder of technology which is a process, has many applications to control and monitor the industrial work, production, and its various complicated work.

The industrial automation system is basically a control system for operating equipment like machinery, boilers, heat treating, switching on the telephone network and so on. To a simpler view, all the thing that is automatic where manual help is low-sized and industrial work is done with the help of the machines and program is called Automation. Now, by the word, Automation Solution it is easy to understand that, in an automatic factory there are many machines operated 24/7.

To make them operate accurately and when any equipment problem emerges to solve them with the techniques and procedures is the part of the industrial automation solution. Such as in many factories like cement, mining, manufacture and other factories where there is a constant need for reducing the costs of laboratory analysis by optimizing the quality and quantity of it, there requires advanced laboratory automation and process control system.

To reduce costs and optimize quality for the industry, the process control team offers a complete spectrum of laboratory industrial automation and information system including its operative configuration, sample transportation, result processing and so on. So, basically, automation solutions are based on one’s unique needs and goals and pay for themselves quickly due to lower operating costs, reduced lead times, increased output and more.

Types of Automation: In the automation Section, there are three basic types of Automation. They are:

- Flexible industrial automation solution: Flexible automation is the ability for a robot or system to be quickly and easily re-tasked to change product design both high and low mix manufacturing. While Fixed automation may be less expensive in the short term, it would be able to save costs on future product lines. Some benefits of its to reduce cell size by removing tool changing stations and rack for each part, to decrease floor space, decrease cost of value-adding labor by being able to ID and locate parts versus being placed in a rack manually, can keep the production cost flat by eliminating the need for custom tooling and fixturing on future products.

- Programmable industrial automation solution: Programmable automation is a form of automation for producing products in batches. The products are made in batch quantities ranging from several dozens to several thousand units at a time. For each new batch, the production program must be reprogrammed and changed over time. The programmable automation controller is a term that is loosely used to describe any type of automation controller that incorporates higher-level instruction. The system is used in the industrial control system for machinery in a wide range of industries, including those involved in critical infrastructure. In the programmable automation controller PLC and PAC, all are applicable.

- Fixed industrial automation Solution: Fixed automation is hard automation. As an alternative to robotic integration, Wauseon Machine offers fixed automation solutions. Hard automation can provide a more cost-effective solution and may be better suited for any application. It is a system in which the sequence of processing operations is fixed by the equipment configuration. Each of the operations in the sequence is usually simple.

View our Industrial Attachment Training on Industrial Automation & Instrumentation courses

Benefits of Industrial Automation and its Solutions

There are so many benefits of automation in this modern era. They are:

- Lessen Production cost: By using smart devices like the PLC and SCADA, it will not only reduce the production cost but also it will reduce manual service by making everything automatic through industrial automation.

- Improved quality and reliability: Industrial Automation is precise and repeatable. It ensures the product is manufacturing with the same specification and process every time. Repairs are few and far between.

- Decrease in Part cycle time: In this modern time, manual work can create inaccuracy and complexity with the exaggeration of time. On the other hand, Robotics can work longer and faster which increases the production rate.

- Reduce Waste: Robots are so accurate that the amount of raw material used can be reduced, decrease the costs of waste.

- Saves Local Jobs: In an industrial automation sector, in the past, there needs a higher level of labor due to the work pressure. The more labor, the more cost. But now instead of moving one’s company to lower-labor costs. Now, the automation system can solve this problem and will increase one’s profit. As a result, one can keep one’s company in a current location.

- Stay competitive: Reduction in schedule and cost attracts customers. Industrial Automation helps provide the highest throughput with the least amount of spending.

- It helps one nurture leads more easily: One’s one has the least amount of emails or leads, one needs a path to convert them to sales. That’s the importance of lead nurturing. To keep the potential customer interested engaged in what one is doing.

- Zero dependencies on each time: The best marketing industrial automation software available is easy to set up and to implement. One of the top benefits of a marketing automation solution is that one can set up one’s company only in one time and then automate the entire process once and for all.

- Advanced targeting capabilities: One of the biggest benefits of using Marketing industrial automation to automate one’s customer investment to hyper the target based on customer behavioral, demographic and social data. The best marketing industrial automation software has the capability of segmenting the audience on a number of factors to help the target achieving.

- Exceptional Return on Investment: An industrial automation with a solution is an exceptional return on investment. The profit and opportunities are much higher than the investment. After setting up a machine with a good configuration, we can get a load of productivity for many years at ease. A good automation system can do many things also. Such as:

- It can reduce marketing cost

- Increases throughout or Productivity

- Improved quality or increased predictability or quality

- Increased consistency or output

- Reduced direct human labor costs or expense

To get our products to visit our product site

PLC as an Industrial Automation Solutions

PLC which stands for Programmable Logic Controller has many benefits in the industrial automation sector. Often, it works as an instant solution in the industrial automation industry. Sometimes many works need to do at a time, sometimes an instant full programming change is needed, sometimes a method is needed where many works can be done instantly at a low cost.

PLC is such a kind of device that is reliable, easy to maintain, can troubleshoot and resolve any problem that can jeopardize operations. To some experts, in the future, developers with different programming capabilities, within the company, must work parallel, yet independently of each other, on one automation system. PLC’s next technology forms the basis of the open control platform from Phoenix contact. This solution combines all communication characteristics and advantages of the classic PLC world. With the openness and flexibility of smart devices.

PLC next technology is the new control platform from Phoenix Contact, that opens up numerous possibilities for the user. In addition to the traditional IE 61131 programming, users can now write in high-level languages, such as C, C++, MATLAB Simulink, or an HTML5 code. By PLC new technology one can create its own so-called apps or applications, and use them to individually expand the PLC next Technology platform. This concept ensures the future prove method and its investment protection.

SCADA is an industrial Automation Solution

To maintain an effective flow of data across the Supervisory Control and Data Acquisition system, one can rely on flexible and secure solutions. AUTOSOL offers SCADA software that the world’s largest corporations to be count on. With an ever-growing range of devices, from those with the latest technologies to older equipment whose life must be extended to keep cost down, one expects SCADA communication to be dependable and occur in real-time. And in today’s environment, one depends on being able to securely transmit, monitor, and control data, regardless of the number of devices in the system.

It is a real-time industrial process control system used to centrally monitor and control remote or local industrial equipment such as motor, valves, pump, etc. SCADA has many benefits, such as to the graphic representation of the entire system, continuous information at Operator Workstations, Automatic control, Remote Control, to alarm, to report, online monitoring, excel report generator and so on.

It saves money and time, remotely monitor, less manual needs, monitors the section of the plant, increases the production efficiency, to provide alarms for the critical condition, can view and control plant-floor operations from virtually anywhere through web navigation. Many solutions can be found through the SCADA. Such as to maintain automobile production and supply, chemical and pharmaceutical industries, printing industry, energy supply and distribution, trading and service, mechanical and plant engineering and so on.

So, from having all the details about the industrial automation technology, we can say that in this techno-based era where automation is spreading like the wind and in nook and corner of our lives, we can find its importance. In the past, when in a developing country like Bangladesh, there was a constant need for dependency over the foreign country to supply automatic machines and its solution software which takes a ton of money, now is available in our own country.

Many training centers like BAT and others import machines and parts from other countries and make it familiar to many people by giving training in it. So that engineering students of Bangladesh can be an expert in it, and they can create the solution in the Automation technology. In the automation solution, the Programmable logic controller and Supervisory Control and Data Acquisition have made a huge impact.

View our Advance Training Course on SCADA

Benefits of Industrial Automation

There are tons of benefits of industrial automation in this era. There we can hardly found any work where industrial automation doesn’t leave its footprints. In this world, where a load of the population is surviving, it needs a huge amount of survival production. Need tons of food, clothe, medicines, daily using products and products for luxuries. All these things are the fruits of industrial automation.

Quite simply, Automation makes our life easier. Automatic windows in our cars keep us from fiddling with a mechanical crank to get a breeze, automated bill paying ensures that we never to forget to pay the electric bill, and how would we ever get our grocery carts out of the stores without automatic solutions.

Manufacturing would be nothing without automation. From robots to industrial machines all are done by the help of automation.

Automation reduces cost

Employing robots is cheaper than employing human workers. After the initial cost of a factory robot, the only costs are energy, maintenance, and repairs. This results in big savings when compared to annual salaries for human workers, and a higher return on investment.

Industrial automation provides more production with fewer workers. All you need is a handful of employees to monitor and operate machinery rather than a floor full of laborers.

High production costs mean lower profits. Lower production costs mean lower profits. Lower production costs and higher production translates to more affordable goods for consumers.

Automation improves quality

Humans are great, but we’re prone to error. Industrial motion control systems are more precise than human workers and cut out the factor of human error. Not only does this result in a higher quality product, but it also delivers a more consistent final product.]

Automation improves efficiency

Even the human brain is more powerful than any technology, but for accuracy, we have to depend on automation which works in a speedy way with a systematic program. Robots work faster than humans, harder than humans, and they can operate 24/7.

When Ford introduced the first moving assembly line to their plant, they whittled the time it took to make a vehicle from 12 hours to 90 minutes. Today, thanks to the industrial automation- as well as over 70 production facilities-Ford makes roughly 16 vehicles every 60 seconds around the world.

Automation increases human safety

Increases production and lower costs are obviously important to manufacturing, but added safety is one of the most valuable benefits of industrial automation. Robots remove humans from dangerous work environments.

People are rather fragile, especially when compared to machines. Automation removes workers from exposure to hazardous chemicals, heavy objects, back-breaking labor, poor air quality, extreme temperatures, and other hazardous working conditions.

Automation makes manufacturing better

Industrial automation not only makes manufacturing more profitable and more efficient, but it also optimizes the entire process. Machinery frees humans to fine-tune processes, improve technologies, and focus on the work that can’t be automated. This leads to new, innovative products, increased customization, and better consumer experience.

Advantages and disadvantages of Automation

Advantages commonly attributed to automation include higher production rates and increased productivity, more efficient use of materials, better product quality, improved safety, shorter workweeks for labors, and reduced factory lead times. Higher output and increased productivity have been two of the biggest reasons for justifying the use of automation. Despite the claims of high quality from good workmanship by humans, automated systems typically perform the manufacturing process with less variability than human workers, resulting in greater control and consistency of product quality. Also, increases process control makes more efficient use of materials, resulting in less scrap.

Another benefit of automation is the reduction in the number of hours worked on average per week by factory workers. About 1900 the average workweek was approximately 70 hours. This has gradually been reduced to a standard workweek in the United States of about 40 hours. Mechanization and automation have played a significant role in this reduction. Finally, the time required to process a typical production order through the factory is generally reduced with automation.

The main disadvantage often associated with automation, worker displacement, has been discussed above. Despite the social benefits that might result from retraining displaced workers for other jobs, in almost all cases the worker whose job has been taken over by a machine undergoes a period of emotional stress, in addition to displacement from work, the worker may be displaced geographically. In order to find other work, an individual may have to relocate, which is another source of stress.

Other disadvantages of automated equipment include the high capital expenditure required to invest in automation, a higher level of maintenance needed than with a manually operated machine, and a generally lower degree of flexibility in terms of the possible products as compared with a manual system.

Also, there is a potential risk of automation technology that will ultimately be subjugated rather than serve humankind. The risks include the possibility that workers will become slaves to automated machines, that the privacy of humans will be invaded by vast computer data networks, that human error in the management of technology will somehow endanger civilization, and that society will become dependent on automation for its economic well-being. So, we can understand that how important automation technology is.

View our All course

Greate Blog

Good day! Do you use Twitter? I’d like to follow you if that would be okay.

I’m undoubtedly enjoying your blog and look forward to new updates.

Yes I use Twitter Link:https://twitter.com/batplcbd1