Industrial Automation Solutions

Introduction to Industrial Automation Solutions

The industrial automation solution is basically a control system for operating equipment like machinery, boilers, heat treating, switching on the telephone network and so on. To a simpler view, all the thing that is automatic where manual help is low-sized and industrial work is done with the help of the machines and program is called Automation. Now, by the word, Automation Solution it is easy to understand that, in an automatic factory there are many machines operated 24/7.

To make them operate accurately and when any equipment problem emerges to solve them with the techniques and procedures is the part of the industrial automation solution.

To reduce costs and optimize quality for the industry, the process control team offers a complete spectrum of laboratory industrial automation and information system including its operative configuration, sample transportation, result processing and so on.

Types of Automation

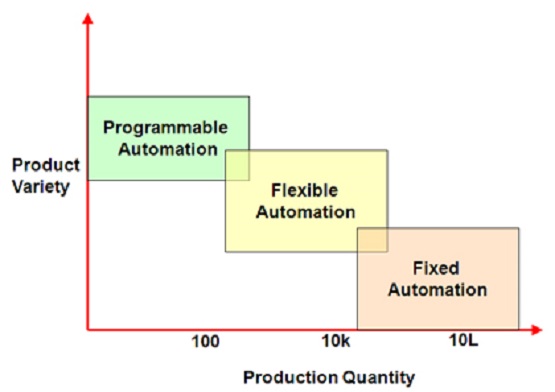

In the automation Section, there are three basic types of Automation. They are:

- Flexible industrial automation solution: Flexible automation is the ability for a robot or system to be quickly and easily re-tasked to change product design both high and low mix manufacturing.

- Programmable industrial automation solution: Programmable automation is a form of automation for producing products in batches. The products are made in batch quantities ranging from several dozens to several thousand units at a time. For each new batch, the production program must be reprogrammed and changed over time.

- Fixed industrial automation Solution: Fixed automation is hard automation. As an alternative to robotic integration, Wauseon Machine offers fixed automation solutions.

Benefits of Industrial Automation and its Solutions

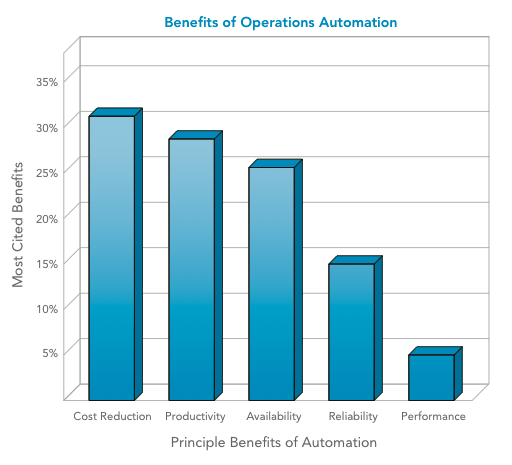

There are so many benefits of automation in this modern era. They are:

- Lessen Production cost: By using smart devices like the PLC and SCADA, it will not only reduce the production cost but also it will reduce manual service by making everything automatic through industrial automation.

- Improved quality and reliability: Industrial Automation is precise and repeatable. It ensures the product is manufacturing with the same specification and process every time. Repairs are few and far between.

- Decrease in Part cycle time: In this modern time, manual work can create inaccuracy and complexity with the exaggeration of time. On the other hand, Robotics can work longer and faster which increases the production rate.

- Reduce Waste: Robots are so accurate that the amount of raw material used can be reduced, decrease the costs of waste.

- Stay competitive: Reduction in schedule and cost attracts customers. Industrial Automation helps provide the highest throughput with the least amount of spending.

- It helps one nurture leads more easily: One’s one has the least amount of emails or leads, one needs a path to convert them to sales. That’s the importance of lead nurturing. To keep the potential customer interested engaged in what one is doing.

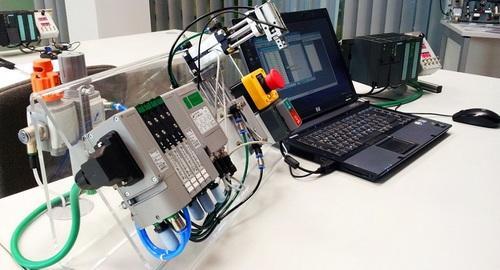

PLC as an Industrial Automation Solutions

PLC which stands for Programmable Logic Controller has many benefits in the industrial automation sector. Often, it works as an instant solution in the industrial automation industry.

PLC is such a kind of device that is reliable, easy to maintain, can troubleshoot and resolve any problem that can jeopardize operations. To some experts, in the future, developers with different programming capabilities, within the company, must work parallel, yet independently of each other, on one automation system.

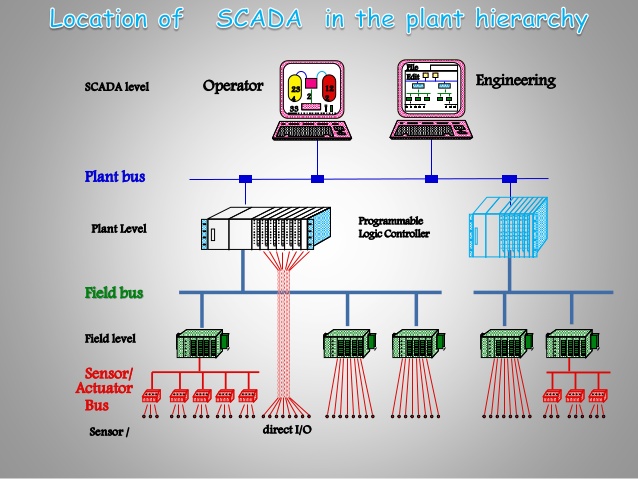

SCADA is an industrial Automation Solution

To maintain an effective flow of data across the Supervisory Control and Data Acquisition system, one can rely on flexible and secure solutions. AUTOSOL offers SCADA software that the world’s largest corporations to be count on.

It is a real-time industrial process control system used to centrally monitor and control remote or local industrial equipment such as motor, valves, pump, etc. SCADA has many benefits, such as to the graphic representation of the entire system, continuous information at Operator Workstations, Automatic control, Remote Control, to alarm, to report, online monitoring, excel report generator and so on.

It saves money and time, remotely monitor, less manual needs, monitors the section of the plant, increases the production efficiency, to provide alarms for the critical condition, can view and control plant-floor operations from virtually anywhere through web navigation.

So, from having all the details about the industrial automation technology, we can say that in this techno-based era where automation is spreading like the wind and in nook and corner of our lives, we can find its importance.

Many training centers like BAT and others import machines and parts from other countries and make it familiar to many people by giving training in it.

View Our Advance Training Course on SCADA

Benefits of Industrial Automation

Quite simply, Automation makes our life easier. Automatic windows in our cars keep us from fiddling with a mechanical crank to get a breeze, automated bill paying ensures that we never to forget to pay the electric bills, and how would we ever get our grocery carts out of the stores without automatic solutions.

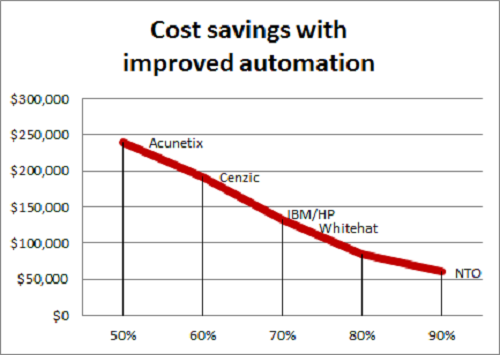

Automation reduces cost

Employing robots is cheaper than employing human workers. After the initial cost of a factory robot, the only costs are energy, maintenance, and repairs. This results in big savings when compared to annual salaries for human workers, and a higher return on investment.

Automation improves quality

Humans are great, but we’re prone to error. Industrial motion control systems are more precise than human workers and cut out the factor of human error. Not only does this result in a higher quality product, but it also delivers a more consistent final product.

Automation improves efficiency

Even the human brain is more powerful than any technology, but for accuracy, we have to depend on automation which works in a speedy way with a systematic program. Robots work faster than humans, harder than humans, and they can operate 24/7.

Automation increases human safety

Increases production and lower costs are obviously important to manufacturing, but added safety is one of the most valuable benefits of industrial automation. Robots remove humans from dangerous work environments.

Automation makes manufacturing better

Industrial automation not only makes manufacturing more profitable and more efficient, but it also optimizes the entire process. Machinery frees humans to fine-tune processes, improve technologies, and focus on the work that can’t be automated. This leads to new, innovative products, increased customization, and better consumer experience.

Advantages and disadvantages of Automation solutions

Advantages commonly attributed to automation include higher production rates and increased productivity, more efficient use of materials, better product quality, improved safety, shorter workweeks for labors, and reduced factory lead times.

The main disadvantage often associated with automation, worker displacement, has been discussed above. Despite the social benefits that might result from retraining displaced workers for other jobs, and lose work originality.

Another disadvantage of automated equipment includes the high capital expenditure required to invest in automation, a higher level of maintenance needed than with a manually operated machine, and a generally lower degree of flexibility in terms of the possible products as compared with a manual system.

Dosage Amoxicillin Pet Amoxicillin cialis prices Viagra 100mg 4st Cytotec Pas D Effet Kamagra Kaufen Nachnahme